Perfect Reeds?

The original article (in German language) was published on https://www.clarissono.de/CS_Archiv/Publikationen/Publikationen.html

This is a translation by www.the-clarinets.net. Some paragraphs have been shortened. The copy of the document will remain in the net even if the original article may be removed. Anyway, visiting the website www.clarissono.de is definitely worthwhile (it contains English pages, too).

The path towards reed perfection

Computer assisted production has by now helped a lot to reach the ideal of the perfect reed. The Nuremberg (Germany) based company AW-Reeds has begun to go this way years ago. (AW= Alexander Wilscher, renowned reed manufacturer)

There are two things every clarinettist would love to have:

- The chance to reproduce a reed once you find one that is really good.

- The possibility to experiment with new reed forms, different embouchures and mouthpieces in a structured way, in order to see what gives the best results for the individual player.

Those where the reasons why Martin Spangenberg, solo clarinettist of Munich's philharmonie and professor for Clarinet in Weimar, engaged in the art of reedmaking - and founded a company together with Alexander Willscher and Hermann Uhl for just this purpose. The three men have already gone some steps towards the goal in the pursue of the perfect reed.

The history of clarinet reed production started about 1810 with Ivan Müller. It is a long story and not always a very simple one. In the beginning clarinet reeds were produced by hand and in so far the very personal requirements of players could be considered (most players produced their own reeds). Embouchure, personal conditions, sound ideals, training and geometrics were included spontaneously in the reed production. The idea of ready-made reeds, produced by machines that cut reeds in the ever same geometrics, promised to deliver a standardised, identical quality. And one day, computerised machines might even produce reeds according to individual customers' specification.

While the home production of clarinet reeds was an inevitable necessity for players until the 1950's, the German Gebhard Steuer tried - for the first time - the technical production process of reeds. It was clear to Steuer that this could only be successful with different types of cuts. Clarinettists (and later also Saxophone players) worked together with him to define layouts and cuts. When the first copies of great artist's reeds where sold, only few could afford it. And since many believed, it would save them hours of rehearsing and give them the sound of the famous players, these reeds might have been a disappointment. Musicians often traveled hundreds of kilometers to buy the perfect reed...

In the late seventies the German manufacturers tried to produce the one optimal reed; and its specification is still what we all look for today - the super-reed: easy response, full control in all registers, full heights and easy staccato, a wide dynamic range and a warm and brilliant sound. Every experienced player knows that this is usually not what you can combine in one single reed, and so every reed is a compromise.

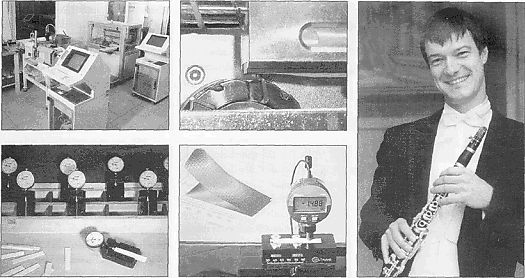

| two CNC-reedcutters at AW-Reeds in Nuremberg. | CNC-controlled cutter for surfaces | Professor Martin Spangenberg |

| The precision of the instrument is being checked | The reed is being digitalised |

Today experience shows that you can use only about two thirds of the reeds coming out of the box. Finding a perfect reed is a coincidence. Even the quality mark "tried out" does not guarantee that you will like the reed, but it will on the other hand increase the cost of production and this made most producers stop the manual control for economical reasons: People just were not ready to pay more for it if there is no real advantage. The success of companies like Vandoren lies in the reasonably priced output of large numbers of reliable, fair average quality.

... but in the end everybody wants individual reeds

Considering the number of factors that make one reed different from the other, there clearly will never be the perfect reed for every purpose and every player. But it appears likely that you can reproduce - to a reasonable extend - the factors that make a reed excellent for your purpose. This can be done with very precise measuring and cutting machines.

In order to reach this aim the German reed maker Alexander Willscher collected data for the production of mouthpieces and reeds alike. In the beginning he experimented with hard metal forms as a master for copies, but later on, when CAD and CNC became available, you could see that a model used as copy master could be just digital, too. Since digital models can be created in large numbers and it is easy to experiment with them, the perfect individual reed becomes a more realistic vision. So Alexander Willscher founded, together with Martin Spangenberg and Hermann Uhl, the company AW-Reeds. They constructed the CNC cutter that could produce any type of reed you could think of without the use of expensive metal models.

Limited reed-mouthpiece combinations

The large number of variants forced the manufacturers to play with the many parameters, but in the end reduce them by reality tests, comparisons and the exclusion of improbable exotic variants. The theoretical model was again improved by many tries and errors; and resulted finally in a small number of successful, proven reed models. Just after production started, players, who quickly understood what might be possible, demanded specialities. And of course many asked for reeds for their beloved E flat and bass instruments. Willscher answered the requests and improved his machines step by step (better bottom sides and better edges due to the wedge machine, constructed by Hermann Uhl.)

After many optimisation steps and with the help of the CNC mill Willscher today is able to produce large quantities of clarinet and saxophone reeds in a standardised quality. Many students and famous players (like Sabine Meyer, Ralph Manno, Joachim Peitz, Rainer Wehle, Ulf Rodenhäuser and others) are ordering their custom made reeds and benefit from the development.

A vast treasure of experience has arisen from the innumerable experiments. So today there is a - though yet limited - offer to consult players in what seems suitable for which purpose. The way to become the perfect player, leads - next to ever intense rehearsing - through finding the perfect reed-and-mouthpiece combination for you for different playing situations. By experimenting again and again you will find certain combinations to be better suited than others.

"It's never been that easy"

Today Martin Spangenberg is more than satisfied with the results: "Although such a project naturally will have its setbacks and will show a lot of unexpected difficulties, we have created an excellent position to tackle the remaining difficulties. I never have found such good reeds that easily and that is why I am optimistic that our offer will meet the demands of more and more players. The remaining step is a complete synthesis of all components that define a clarinet (not just reeds and mouthpiece). But we need more expert support for that type of field. Everybody is welcome to support us and share his or her experience

Martin Schöttle/Dr. Martin Augustin

MUSIK ZUM LESEN 05

The original article was published on

https://www.clarissono.de

This is a translation by www.the-clarinets.net. Some paragraphs have

been shortened. The document will remain in the net even if the

original article may be removed. Anyway, visiting the website

www.clarissono.de is

definitely worthwhile (it contains English pages, too).